Mechanical Insulation Technology: What’s New for 2023

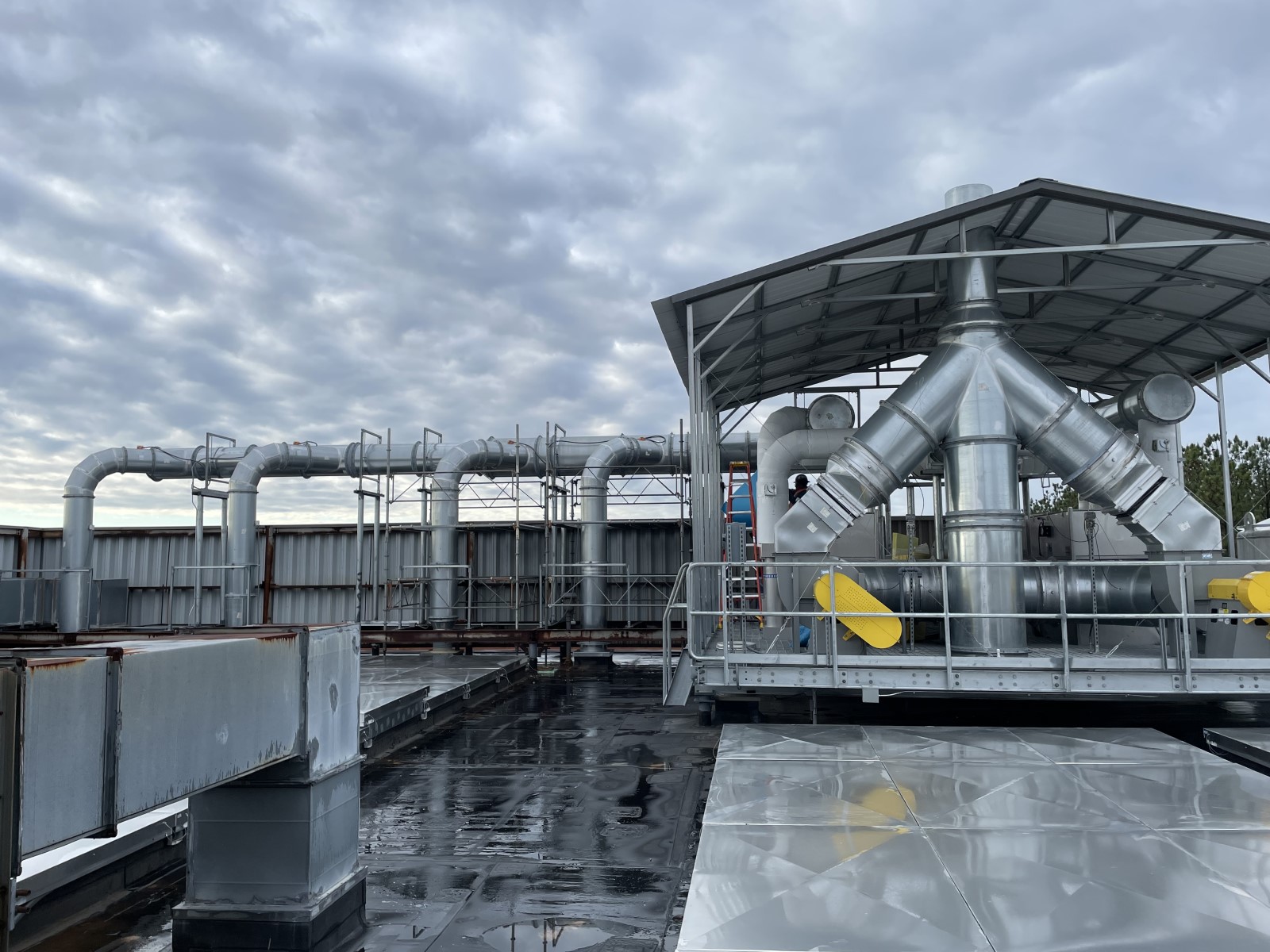

It’s going to be a big year for mechanical insulation technology. Technological breakthroughs, growing demand, and a global gas supply shakeup offer new challenges and opportunities for the industry.

It has also increased awareness of the critical role mechanical insulation plays in reducing greenhouse gas emissions. Read on to learn more about how mechanical insulation will continue to change the world in 2023.

Mechanical Insulation Technologies: A Global Outlook

Despite worries the U.S. economy will enter a recession this year, the outlook for commercial and industrial construction remains strong. Growth of about 6.5% is expected in 2023, suggesting a continued strong national insulation products demand.

Steady Growth

Higher energy costs and ever-tighter environmental and green-building standards are driving demand for more efficient and sustainable insulation products. A recent report estimates the global market for industrial thermal insulation will grow at 4.5% through 2030.

European Chill

Russia’s invasion of Ukraine last year disrupted gas supplies to Europe, spiking prices by up to 150% above 2019-2020 levels. The prospect of two or more winters with gas in critically short supply has changed thinking on the continent.

Insulation Windfall

Europe has been a leader in adopting clean energy and more efficient building standards. Now, the need for proper insulation for mechanical systems will drive the development of innovative new insulation technologies.

6 Areas to Watch in Mechanical Insulation Technology

Innovation never stops in the mechanical insulation industry. New materials are continually being developed and existing materials are made even better. Here are some key areas to keep an eye on this year.

1. Unstoppable Aerogels

The development of innovative new materials for use in mechanical insulation systems is set to continue. Aerogels hold particular promise because of their unique ability to reduce energy loss while allowing troublesome liquid condensate to evaporate.

Developed in the 1930s, aerogels are foams formed by allowing a liquid-based gel to solidify and then removing the liquid. Researchers have returned to the technology in recent years, developing new ways to make the resulting structures more robust and pliant.

Aerogels are now widely available in rolls and sheets, or even spray-on form, for use in protecting mechanical equipment. However, costs for the best-performing materials remain high.

2. It’s a Gas (or a Vacuum)

Highly efficient vacuum or gas-filled insulation products can also be used to insulate mechanical systems. However, these are more difficult to produce in the flexible roll, blanket, or granular forms commonly used for pipe insulation. At this point, they are still used mainly for high-end building insulation.

3. Hot HTI

Steadily rising energy prices worldwide will drive continuing demand for high temperature insulation (HTI) materials for industrial facilities and power plants.

That means go-to options like blanket fiberglass or mineral wool will remain as popular as ever. At the same time, there will be increasing calls for silicone and ceramic products capable of handling the most demanding applications.

Expect rapid innovation of new silicone and ceramic products, and higher prices for glass and mineral insulation materials.

4. Fiber Fears

Worries about the potential health impacts of mineral, ceramic, and glass wool as well as woven products are set to continue. While modern products are much safer than asbestos products, fibers given off when these materials are handled still pose a threat. Some green building codes are now seeking to eliminate or minimize their use.

There is an increased focus on developing alternatives to these fiber-based products even as demand remains high. In the meantime, suppliers need to be transparent with customers about the risks and benefits of products. We also need to ensure employees and insulation contractors always use the right personnel protection when handling wool and woven products.

5. Cell Call

Fiber-based insulation remains the widest-used material in the industry. Now, health and safety concerns are driving growth in the use of cellular insulation materials. Low costs, long life expectancy, and rapidly improving performance are also driving adoption.

Look for this trend to continue, especially as more spray-on, wrap, and blanket solutions— including aerogel products—become available.

6. Evergreen Glass

Fiberglass is gaining popularity as an affordable “green” material with more products made from recycled glass. The use of recycled materials to make insulation products is a hot area for the industry. It’s yet another way in which mechanical insulation earns its stripes as a “forgotten” green technology.

Prepare for the Future With MultiService Industrial

You need a mechanical insulation partner who can deliver tomorrow’s efficiency solutions at a price you can afford. At MultiService Industries, we know how important mechanical insulation is to controlling and predicting prices, especially in commercial and industrial applications.

Talk to us today about your mechanical insulation needs. Our highly experienced team is ready to deliver the right insulation product for your project and your pocket. Click below to learn more.

LEARN MORE ABOUT MULTISERVICE’S MECHANICAL INSULATION SERVICES