Best Commercial Duct Insulation

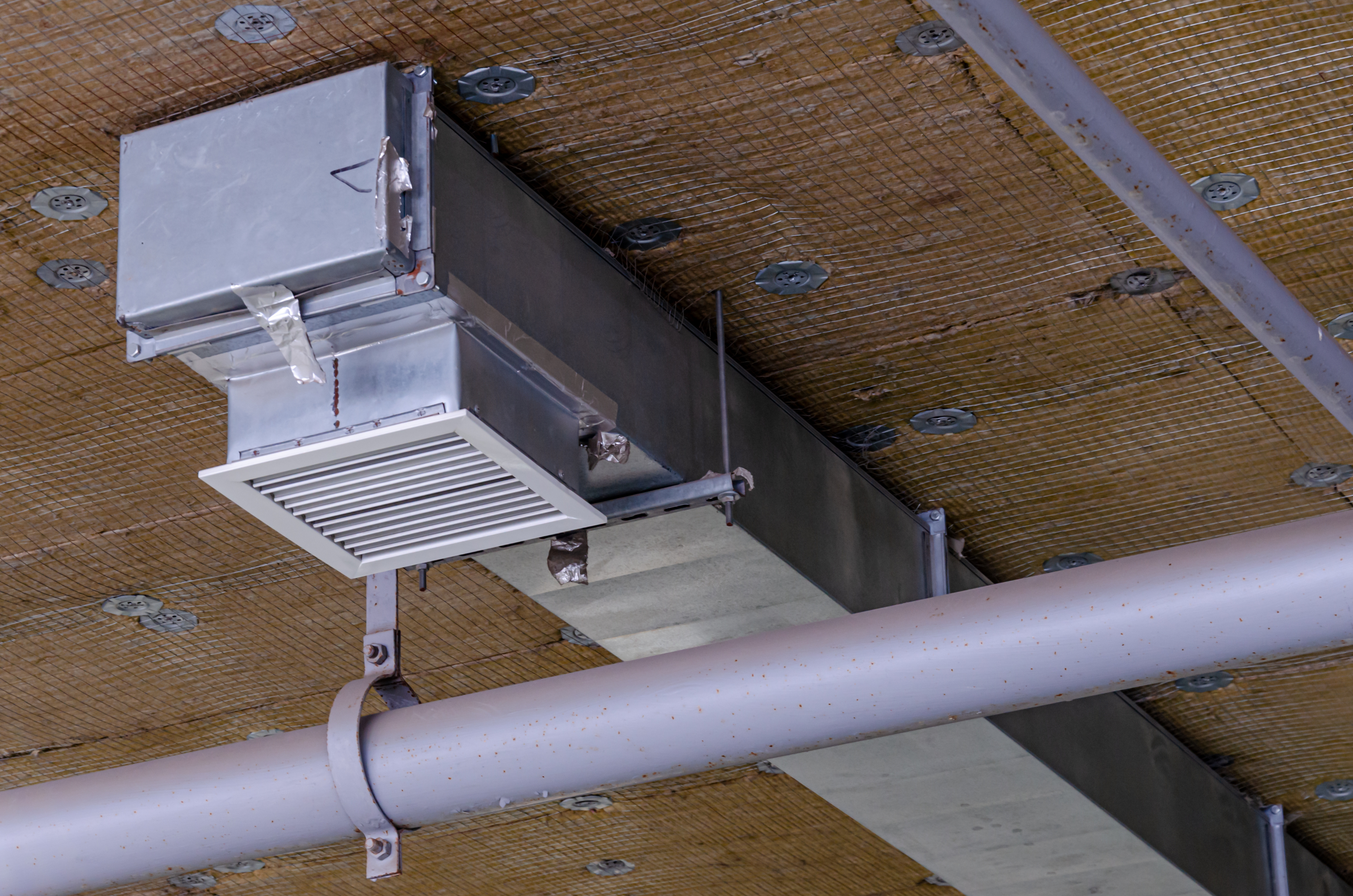

Commercial duct insulation lowers energy costs and improves building comfort. Selecting the right type requires understanding R-value requirements, as well as some knowledge of the types of HVAC duct insulation available.

Continue reading to learn more about choosing the best commercial HVAC duct insulation for your space.

Why Insulate Commercial Ductwork?

Ductwork directs air from blowers, heaters, and cooling coils to the spaces where it’s needed. Most commercial HVAC systems use the variable air volume (VAV) approach where fan speed is adjusted to maintain the target temperature.

Depending on conditions, this can lead to air whistling through the ducts, which increases heat loss or gain, or barely moving at all – which creates many other problems.

Heat transfer is proportional to the Delta T between conditioned air and that outside the duct. The greater the differential the faster heat flows from hot to cold. For this reason, it’s very important to insulate any ductwork that goes outside the building, because this has the biggest impact on energy loss.

Ductwork passing through unconditioned spaces inside the building should also be insulated. The Delta T is unlikely to be as large as that outside the building, but can still be enough to cause appreciable energy waste. In fact, Energy Star found that 20 to 30% of the air that moves through the duct system is lost

More Than Energy Savings

Additional benefits from commercial HVAC duct insulation are noise reduction and condensation prevention.

Noise can occur when airflow is high and duct panels start to vibrate. Duct insulation reduces the transmission of this sound into the occupied space. Condensation can occur when chilled air passes through an unconditioned space where the air is humid. Insulating the ductwork prevents condensation which in turn reduces corrosion.

How Much Insulation Is Needed?

ASHRAE and the IECC are the authorities on HVAC systems and duct insulation, although since 2015 the IECC has provided more detailed guidance. For areas like Virginia and North Carolina, they recommend that ducts passing through unconditioned spaces have a minimum insulation R-value of 6. Ductwork going outside the building should be insulated to R-12.

R-Values and Inches

R-value is the coefficient of heat transfer resistance. A higher number indicates a better resistance to heat flow. Insulating materials include an R-value as part of their specification. This is usually given per inch of thickness, so if a material has an R-value of 6, two inches will meet the IECC requirement for R-12.

Considerations When Choosing Commercial Duct Insulation

The primary factors are of course cost and insulating performance. Usually, the goal is to achieve the minimum R-value required at the lowest cost. However, other factors that may influence this decision are:

- Space available

- Sound dampening

- Fire protection

- Health risks

- Likelihood of mold growth

- Sustainability concerns

Space Available

Insulation is going to make ductwork bulkier. For new construction, this must be taken into account during design. For a retrofit, space constraints may force the use of a higher R-value material, even if it increases costs.

Sound Dampening

HVAC noise is rarely a concern in places like factories or warehouses. In commercial buildings, it can be an important consideration, with high levels contributing to an unpleasant work environment.

If noise reduction is one of the goals for duct insulation, check the Noise Reduction Coefficient (NRC) on the materials under consideration. Remember that a higher number means better sound absorption.

Fire Protection

Some insulating materials won’t combust, and others will. Make sure you know what you are getting and check for compliance with all relevant codes.

Health Risks

All materials can have hazards, some worse than others. Fiberglass and mineral wool insulating materials are not considered carcinogens but can cause skin irritation. This should only be a concern during installation. Some types of spray foam insulation can cause asthma. Check the known risks of the materials being considered.

Likelihood of Mold Growth

Moisture resulting from condensation can lead to mold. Some insulating materials are more conducive to mold growth than others. This should be considered if insulating unconditioned spaces in a region with high temperatures and humidity.

Sustainability Concerns

Duct insulation can help earn points for LEED® certification. However, some insulation is more sustainable than others. Some will give off fumes and are not recyclable. Other types incorporate recycled materials and can themselves be recycled.

Options for Commercial Duct Insulation

Many materials are available, in various forms. Those MultiService works with most often are:

- Polyisocyanurate – a closed-cell rigid foam known as ISO or PIR, R-value ranges from 6.2 to 7.2

- Rock Wool – a trade name for a mineral fiber insulating material, R-value of 3.0 to 3.2

- Fiberglass Blanket – R-value ranges from 2 to 4, depending on the composition

- Fiberglass Board – one of the easier materials to install, R-value ranges from 4.2 to 4.3

- Spray Foam – used in places that are hard to reach, can give off fumes, R-value of 7.2

- Loose-Fill Insulation – can be fiberglass or other materials, speak with your supplier for details

Professional Advice on Commercial Insulation

The appropriate duct insulation lowers building operating costs and improves the comfort of those working there. MultiService specialists understand the options available and the pros and cons of each.

For advice on the right type of insulation for the ductwork in your commercial building, click below.