Understanding the Different Types of Pipe Coatings

Not all types of pipe coatings are created equal, and choosing the right one is crucial to ensuring your pipes’ long-term protection and performance. The effectiveness and longevity of a coating depend on selecting the proper material for your specific application. Choosing the wrong coating can result in premature failure, ineffective protection, safety hazards, as well as costly repairs and wasted investment. That’s why understanding the different types of pipe coatings, their benefits, and their ideal applications is key to making an informed decision.

At Multiservice Industrial, we’re experts in industrial coatings and have the experience and knowledge to help you choose the best pipe coating for your needs. Whether you’re dealing with harsh chemicals, extreme temperatures, or challenging physical conditions, we’re here to guide you toward the right solution. Below, you’ll learn about the most common types of pipe coatings, their advantages, and the industries they are best suited for.

The Importance of Choosing the Right Pipe Coating

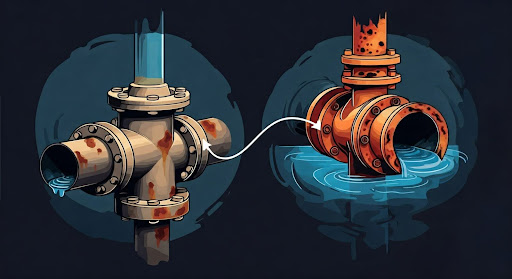

Pipe coatings are essential in protecting your pipes from corrosion, abrasion, and other environmental factors that can shorten their lifespan. If you choose the right coating, it will serve as a strong protective barrier, preventing damage from exposure to moisture, chemicals, and even high temperatures. They can also provide thermal insulation, reduce friction, and improve aesthetic appeal.

Pipe coatings are essential in protecting your pipes from corrosion, abrasion, and other environmental factors that can shorten their lifespan. If you choose the right coating, it will serve as a strong protective barrier, preventing damage from exposure to moisture, chemicals, and even high temperatures. They can also provide thermal insulation, reduce friction, and improve aesthetic appeal.

However, the wrong choice can leave your pipes vulnerable, leading to costly repairs, operational downtime, and even safety hazards, ultimately affecting a business’s bottom line and reputation.

The right type of coating is determined by factors like environmental conditions, chemical exposure, temperature, and mechanical stresses. Industry standards and specific application requirements also guide the choice. At Multiservice Industrial, we ensure that every coating solution is tailored to the unique needs of your operation.

Types of Pipe Coatings and Their Benefits

1. Fusion Bonded Epoxy (FBE)

Fusion bonded epoxy is one of the most popular pipe coatings due to its strong adhesion and exceptional corrosion resistance. This coating creates a hard, durable layer that protects pipes from harsh environmental elements, making it ideal for both underground and underwater applications.

| Fusion Bonded Epoxy (FBE) | |

|---|---|

| Best For |

FBE is perfect for applications where corrosion protection is essential, particularly in underground or submerged pipelines. |

| Benefits |

Excellent resistance to corrosion |

| Common Applications |

Oil and gas pipelines |

2. Polyethylene Coating

Polyethylene coating is flexible and highly resistant to abrasion, making it an excellent choice for pipes that are exposed to physical wear. It also provides some chemical resistance, though not as robust as epoxy coatings.

| Polyethylene Coating | |

|---|---|

| Best For |

Polyethylene coatings are best used in environments where pipes are exposed to physical wear and tear, such as in mining, marine, and construction industries. |

| Benefits |

High abrasion resistance |

| Common Applications |

Buried pipelines |

3. Coal Tar Enamel Coating

Coal tar enamel coatings are known for their excellent protection against corrosion, especially in harsh environments. This type of coating is commonly used in areas that are exposed to water, soil, and chemicals.

| Coal Tar Enamel Coating | |

|---|---|

| Best For |

Coal tar enamel is commonly used in industries like oil and gas, where pipes are exposed to corrosive elements both in the ground and underwater. |

| Benefits |

Strong protection against corrosion |

| Common Applications |

Marine environments |

4. Polyurethane Coating

Polyurethane coatings are primarily used for their excellent UV resistance and high durability. They provide strong protection against outdoor elements and can also resist abrasion and chemicals.

| Polyurethane Coating | |

|---|---|

| Best For |

Polyurethane coatings are ideal for pipes and equipment exposed to the elements, especially in industries like construction and automotive. |

| Benefits |

Exceptional UV resistance |

| Common Applications |

Storage tanks |

5. Phenolic Coating

Phenolic coatings are highly effective at withstanding high temperatures and aggressive chemicals, making them suitable for demanding industrial applications. They provide excellent protection against corrosion and can handle high-pressure conditions.

| Phenolic Coating | |

|---|---|

| Best For |

Phenolic coatings are best suited for industries where high temperatures and exposure to chemicals are common, such as petrochemical and manufacturing operations. |

| Benefits |

High temperature and chemical resistance |

| Common Applications |

Chemical processing pipelines |

Choosing the Right Pipe Coating

Choosing the right pipe coating is more than just selecting a material based on cost or appearance. It’s about understanding the specific conditions your pipes will be exposed to and selecting a coating that can provide the best protection. Factors like temperature, chemical exposure, and physical stress all influence the performance of different coatings.

Coating pipes and equipment prevents corrosion, extends service life, improves efficiency, reduces maintenance costs, and enhances safety. It also improves the appearance and can add specific functionalities like fire resistance.

At Multiservice Industrial, we use our in-depth knowledge of industrial coatings to help you make the right choice for your pipes. We understand how critical it is to protect your investment and ensure the longevity of your systems. Our team of experts will guide you through the selection process, considering all the factors to determine which coating best fits your needs.

Why Multiservice Industrial is Your Best Choice For Industrial Coatings

Choosing the right pipe coating isn’t just about picking the material — it’s about working with a company that understands your needs and can deliver high-quality results. At Multiservice Industrial, we have extensive experience in industrial coatings and a track record of successful projects. Our team of experts is dedicated to providing customized solutions that ensure your pipes stay protected, no matter the conditions.

Our commitment to customer service, precision, and expertise makes us the ideal choice for your pipe coating needs. We understand the complexities of different coatings and industries, ensuring you get the right solution the first time.

Don’t Leave Your Pipes Vulnerable!

To ensure their longevity and efficiency, it’s vital to protect your pipes with the right coating. At Multiservice Industrial, we provide expert guidance and high-quality pipe coatings tailored to your specific needs.

Contact us today to discuss your project and find the perfect coating solution for your pipes!